Our Machines and Their capabilities

Inertia Welder

Our Inertia Weld Line

Advantages of Inertia Welding

Unique welding capabilities

Inertia Welding, also referred to as Rotary Friction Welding, creates a 100% bond of the contact area – such as a full-section weld around a diameter on the OD or ID of a tube – creating joints of forged quality. The weld properties are superior to welds created with fusion processes, such as MIG or TIG welding. This results in a higher strength bond and greatly increased design flexibility of part.

Ecologically friendly and energy efficient

Inertia Welding is an environmentally friendly process that requires no consumables, flux, filler material, or shielding gases to run. Plus, there’s no weld splatter. It’s also energy efficient because it uses the least energy consumption of all welding processes.

Faster Weld Cycles

Weld Cycle production times can be reduced, meaning that more parts can be joined in less time, since the inertia welding process is significantly faster than more conventional methods of welding. Many rotary friction welds are accomplished in mere seconds.

Machine Controlled Process

The machine-controlled inertia weld process is consistent and repetitive, eliminating human error while producing weld quality that is independent of an operator’s skill level. The process parameters are easily controlled, repeatable, and monitored, allowing for real-time and statistical monitoring of the parameters.

Join Dissimilar Materials to Reduce Material Costs

Metal combinations not normally considered compatible using conventional welding methods can be joined by inertia welding, such as aluminum to steel, copper to aluminum, titanium to copper, and nickel alloys to steel. This creates significant cost savings because engineers can design bimetallic parts that use expensive materials only where needed. Industries like automotive and aerospace will friction-weld dissimilar materials as a way of light weighting components for their applications.

Inertia Welder

The unique process of Inertia welding creates a 100% bond.

Induction Coil

The Induction Coil is used to stress relieve the inertia weld.

Sub Arc Weld

Flux removes any oxygen from the weld.

Engine Lathe

Turning down the weld smooths the weld even with the tool joint.

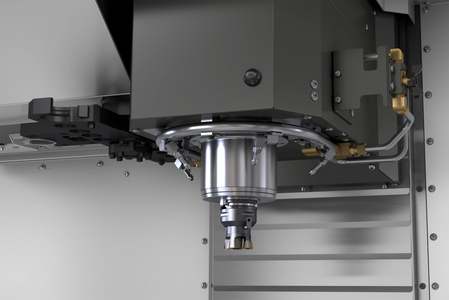

DMG Mori Seiki NLX 2500

Turning Lathe

- Handles Various Workpieces with a Highly Rigid Bed, Powerful Turning Capability and Outstanding Milling Performance with the Matured Built-In Motor turret.

- Max. Turning Diameter 14.41"

- Max. Work Piece Length with a Tailstock 49.41"

- Max. Chuck Size 10"

- Max. Bar Capacity Diameter 4.01"

- Free Definition of Contours, Pitches and Gears Possible

- Creation of Large Transmission Threads, Which Can Not Be Manufactured By Simple Thread Chasing

- Trapezoidal, Buttress and Knuckle Thread Easily Programmable at the Machine

- Screw Conveyor with Any Profile Geometry

- Ball Screw Nut with Cross Holes Simple to Realize

DMG Mori Seiki SL-403

CNC LATHE

- Machines are Equipped with Dual Diameter Chucks with 7.250" Thru 19.250" Diameter Spindle Capacity.

- 40 HP

- 1500 Max RPM

- Turning Diameter 27"

- 36" Swing

- 37" Machine Length

- All Equipped with Tailstocks

- F32IB Controls with Built in Capps Conversational Programming

- The Spindle Drive Utilizes a High Output, High-Torque AC Spindle Motor That Can Handle Heavy and/or Continuous Cutting of a Variety of Workpieces

- Maximizes and Stabilizes Speed and High Precision.

Lodge & Shipley RXE 2516 Lathe

- Maximum Swing Over Ways: 26-1/2”

- Maximum Swing Over Cross Slide: 20”

- Distance Between Centers: 120”

- Spindle Hole: 13”

- Spindle Speeds: 6 to 338 RPM

- Motor: 25 Hp 230-460/3/60

- Capable of Running 12" and Lower Pipe

- 20ft Bed Capable of Running 22" OD Parts

Hwacheon Hi Tech 700

CNC Lathe

- Extra Large Horizontal Turning Center

- Advanced, Patented Design Prevents Deterioration of the Workpiece From Thermal Displacement.

- Max Cutting Diameter of 25.59"

- Max Cutting Length of 78.74"

- Spindle Speed 1800 RPM

- Standard Cutting Diameter 15"

Lehmann Manual Lathe

- 11" Chuck Opening

- Capable of Machining 20" parts

- 6ft Bed

Summit 19-4X80 Manual Lathe

- Swing Over Bed 19"

- Swing Over Cross Slide 10-3/4"

- Swing in Gap, Gap Length 27", 15-3/8"

- Distance Between Centers 80

- Diameter of Spindle Bore 3"

HAAS VF SERIES

CNC MILL

- 40 Taper

- 30" X Axis

- 16" Y Axis

- 20" Z Axis

- 8.1K RPM

- 20-40 Tool Capacity

Yama Seiki BM-1460

Mill

- Rigid CAT 50 Machine

- High Pressure Through Spindle Coolant

- 3 Axis

- X Axis 59.1"

- Y Axis 25"

- Z Axis 23 "

- X&Y Axis Rapid Feed Rate 20 IPM

- Z Axis Rapid Feed Rate 18 IPM

Pipe Straighteners

Drill Co Pipe Straightener

Capable of straightening larger oil field drilling pipe.

We also have a pipe straightener for smaller pipes.

Click the button below to see more!

Copyright © 2024 B&M Tool Company - All Rights Reserved.

Powered by GoDaddy Website Builder